- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

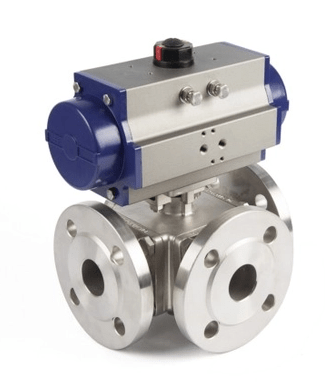

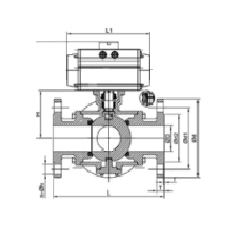

PNEUMATIC ACTUATED THREE WAY FLANGED BALL VALVE

Middleeast Valve is the leading Manufacturer and Supplier of Pneumatic Actuated Three Way Flanged Ball Valve, designed for accurate flow direction control in automated systems. With flanged ends for convenience in installation and a three-way configuration for mixing or diverting flow, these valves are crucial in intricate industrial processes demanding flexibility and efficiency.

Definition

A Pneumatic Actuated Three Way Flanged Ball Valve is a quarter turn valve driven by a pneumatic actuator to manage flow among three different ports. The flanged ends offer a leak-proof and secure connection, while the three-way design enables diverting, mixing, or shutting off flow paths.

Key Components

- Valve Body: Constructed of heavy-duty materials like stainless steel or carbon steel.

- Ball: Drilled in “L” or “T” port patterns based on flow requirements.

- Seats and Seals: Usually PTFE for chemical resistance and sealing.

- Pneumatic Actuator: Mechanism driven by air that automates the operation of the valve.

- Flanged Ends: Facilitate simple bolt-on fitting in pipeline systems.

Working Mechanism

When air pressure is applied to the actuator, it turns the ball within the valve to alter the flow direction between ports. Depending on the port arrangement, the valve can blend flows or redirect them from one port to another, all with rapid, automatic control.

Benefits

- Streamlines piping systems by integrating functions

- Rapid and remote actuation

- Simple to install and maintain

- Long-lasting under high pressure and corrosive conditions

- Secure flanged connections minimize leakage

Applications Typically used in:

- Chemical Industry

- Petrochemical Facilities

- Water Treatment Plants

- Power generation

- Oil and Gas

Why is it Needed?

These valves decrease system complexity, enhance automation and provide solid multi-directional flow control.

Why Purchase from Us?

Middleeast Valve provides premium quality, tailor-made valves with technical expertise, competitive prices, and timely delivery in worldwide markets.