- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

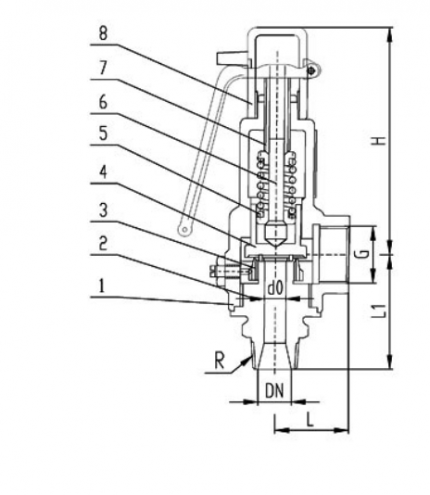

Thermal Safety Valve Supplier in Kuwait: Safeguarding Systems from Excess Heat

Middleeast Valve is the best Thermal Safety valve supplier in Kuwait. These valves are sometimes referred to as a thermal relief valve, which is a specific kind of pressure relief valve created to safeguard pressurized systems and equipment from overpressure situations that may develop as a result of temperature increases.

Working Mechanism:

It work by incorporating a temperature-sensing device, usually a bimetallic strip or wax cylinder, to sense temperature change. When the temperature of the system reaches a given limit, the thermal element is either triggered or expands, forcing the actuator against the valve. The valve opens since it is pushed open by this force, dissipating excess heat or pressure and hence preventing the system from damage. Upon return to a safe temperature level, the valve closes in order to seal the system safely.

Advantages:

1)Tight Sealing

2)Low Maintenance

3)Minimal Pressure Drop

4)Corrosion Resistance

5)Easily Automated

Applications:

1)Paper and Pulp Industry

2)Mining

3)Chemical Processing

4)Power Plants

5)Wastewater Treatment

6)Pulp and Paper

7)Oil and Gas Industry

Description:

Available Materials: Cast iron, Ductile Iron, WCB, SS304, SS316, CF8, CF8M, WC6, WCC, LCB, LCC

Class: 150 to 2500

Nominal Pressure: PN10 to PN450

Size: ½” to 40”

Operation: pilot-operated, pneumatic and electric