- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

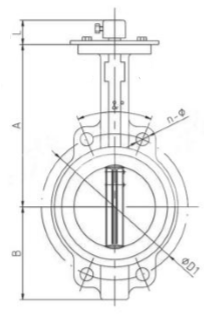

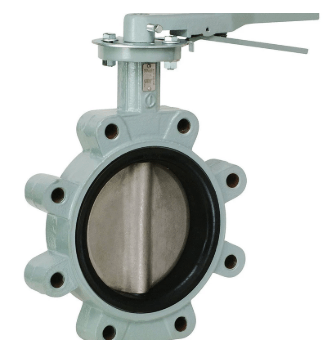

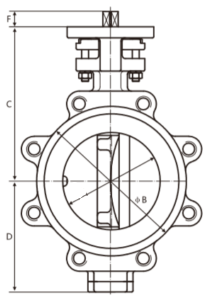

Titanium Butterfly Valve

Middleeast Valve is top valve manufacturing industry and offers high performance flow control solution with the robust and corrosion resistant Titanium Butterfly Valve for uses where strength and reliability are imperative. This valve is designed to work well under severe condition. It is ideal for use in industries dealing with aggressive chemical, seawater or high pressure system.

Definition

A Titanium Butterfly Valve is a quarter turn valve for controlling or restricting flow by an actuating rotating disc placed at the center of the pipe. Its titanium materials provide better strength, light material, and much better corrosion-resistance, even in harsh surroundings.

Major Components

- Body: The principal shell, which consists of titanium as a durable material

- Disc: The actuated part that initiates or completes flow

- Stem/Shaft: Mounts the disc to the handle or actuator

- Seat: Creates a seal between the disc and valve body

- Actuator/Handle: Employed to manually or automatically actuate the valve

Working Mechanism

When the handle or actuator is rotated, the stem turns the disc parallel or perpendicular to flow. In the open position, the disc permits full flow; in the closed position, it seats tightly to prevent flow. The design of the valve provides a low pressure drop and rapid operation.

Advantages

- Superior corrosion resistance from seawater, acids, and chemicals

- Structurally strong yet lightweight

- Simple to operate and maintain

- Economical for big pipe sizes

- Long lasting

Industries Supported

- Desalination

- Chemical Process

- Offshore & Marine

- Oil & Gas

- Water Treatment

- Power Generation

Why Is It Needed?

Standard valves are short-lived in corrosive or high-temperature applications. A Titanium Butterfly Valve provides longevity, safety, and performance with little maintenance.

Why Purchase From Us

Middleeast Valve provides application-specific, custom-engineered Titanium Butterfly Valves to international specifications. We give you quick shipping, technical support, and answers specific to your application.