- Control Valve

- Pneumatic Control Valve

- Pneumatic Angle Control Valve

- 3 Way pneumatic Diaphragm Control Valve

- 3 Way Converging and Diverging Control Valve

- Fluorine Lined Single Seat Control Valve

- Pneumatic Cage Control Valve

- Pneumatic Double Seat Control Valve

- Pneumatic Single Seat Globe Control Valve

- Pneumatic Flow Control Valve

- Pneumatic Sleeve Type Control Valve

- Pneumatic Actuated Globe Type Control Valve

- Electric Actuated Control Valve

- Pneumatic Control Valve

- Cryogenic Valve

- Pressure Reducing Valve

- Safety Valve

- Check Valve

- Gate Valve

- Butterfly Valve

- Globe Valve

- Ball Valve

- Electric Actuated Valve

- Electric Actuated Ball Valve

- Electric Actuated Butterfly Valve

- Electric Actuated Gate Valve

- Electric Actuated Globe Valve

- Pneumatic Actuated Valve

- Plunger Valve

- Strainers

- Steam Trap

- Knife Gate Valve

- Speciality Valve

- Alloy 20 Valve

- Duplex Valve

- Super Duplex Valve

- Hastelloy C276/B3 Valve

- Aluminium Bronze Valve

- Titanium Valve

- Bronze Valve

- Monel Valve

- Triple Duty Valve

- Suction Diffuser

- Diaphragm Valve

- Plug Valve

- Foot Valve

- Air Release Valve

- Surge Anticipator Valve

- Needle Valve

- Balancing Valve

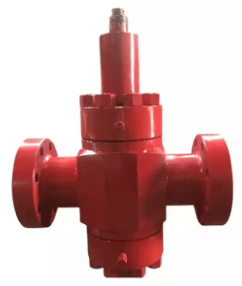

Mud Gate Valve Suppliers in Saudi Arabia: Tough Flow Control Solution

Middleeast valve is one of the best Mud gate valve suppliers in Saudi Arabia. It is designed specifically to handle the challenges posed by abrasive and viscous fluids like mud or slurry. They are engineered with sturdy materials and construction to withstand the abrasive nature of these fluids while maintaining efficient flow control.

Components:

- Valve Body: Constructed from forged steel to tolerate pressure as well as corrosion

- Gate: Solid or split design for rapid shut-off

- Seats: Metal-seated or resilient for good sealing reliability

- Stem: Connects actuator or handwheel to gate

- Bonnet: Encloses stem and adds pressure integrity

Working Mechanism:

Mud gate valves work by lifting or dropping the gate within the body. When the valve is open, free passage of drilling mud occurs through the full bore. When closed, the gate seals the passage, shutting off the flow. Their straight-through-bore design provides low flow resistance and minimizes the chance of clogging, even with thick or particulate-laden fluids.

Advantages:

- Recommended for abrasive, high-pressure fluids

- Simple operation in the field

- Full bore for a low level of flow restriction

- Easy maintenance and field repairability

- Hardened internal parts for long service life

Functions:

The primary function of mud gate valves is to isolate mud system sections. They also control the flow in the course of drilling operations, minimize spillage, and enable safe handling of pressurized fluids. Their durable design makes them perfect for constant use in harsh field conditions.

Industries:

- Oil and Gas Drilling

- Onshore and Offshore Rigs

- Mud Circulation Systems

- Well Servicing Units

- High-Pressure Fluid Handling Systems

- Chemical Processing

- Power Generation